Today, metal clamps for carpentry can be bought at a store or ordered online. However, you can make them yourself if you wish. Many beginners and experienced craftsmen often choose the second option, since in this case a home-made clip can be made from inexpensive materials at hand that are lying under your feet.

The main stages of work

First of all, we make clamp clamping jaws - this will require two pieces of steel profile pipe 20x20 mm, which must be cut on one side at an angle of 45 degrees. We clean the edges of the lips with a grinder so that there are no burrs.

Then we drill two holes in each sponge. Please note: in one sponge there must be two through holes, in the other one through hole, and the second blind (that is, only one wall of the profile pipe is drilled).

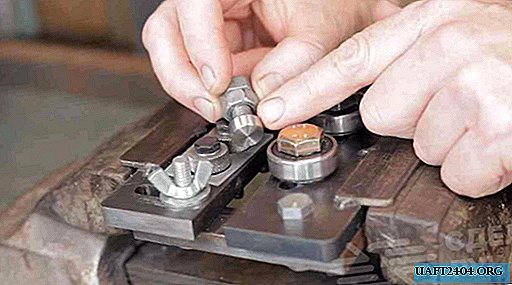

The surface of the sponges must be cleaned from rust, degreased and painted. Next, we connect them with two long bolts with nuts. The result is a simple and budgetary clamp with parallel screws. In this case, the clamping jaws are made of profile, so they are hollow.

We also offer to familiarize yourself with a similar design of a parallel clamp, which has all-metal jaws. Write in the comments below the video what you think about the idea of making such a mini-clamp.