This version of the home-made sandblasting apparatus is made of a propane cylinder with a capacity of 20 liters - it copes well with its task and perfectly cleans the metal surface from rust and dirt. At the same time, the total cost of this unit is much lower than that of factory models.

In the upper part of the container there is a tee with a tap - this is the air inlet, and a hose to the sand mixer leaves from it. Please note that this faucet can be shut off, so if the bottom mixer suddenly clogs, it is blown with compressed air through the cylinder.

Design features sandblasting

The high pressure inlet hose for air supply has an internal diameter of 9 mm (it is often used on oxygen cylinders). At the bottom of the sandblasting unit there is a crane with which you can control the flow of sand. A tee is also installed here, and an oil-resistant hose with an inner diameter of 16 mm is installed at the outlet. Sand with air is blocked by a standard ½-inch ball valve.

The nozzle is made of a candle insulator, a piece of rubber hose is put on top of it, which is fixed with a metal clamp for reliability. In the upper part of the sandblast, a sleeve is welded into which the battery plug is screwed. As a handle for twisting, a chain segment is used, the links of which are welded together.

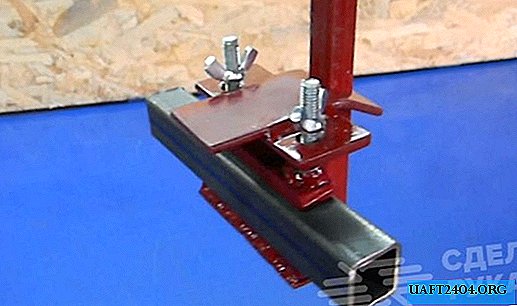

A frame for fastening the wheels is made from scraps of the profile pipe and steel bar, and a handle is welded to the side of the body to make it convenient to transport the sandblasting machine. If you decide to make a similar design, then note that the propane cylinder is turned upside down. For a detailed review of homemade sandblasting, see the video on our website.