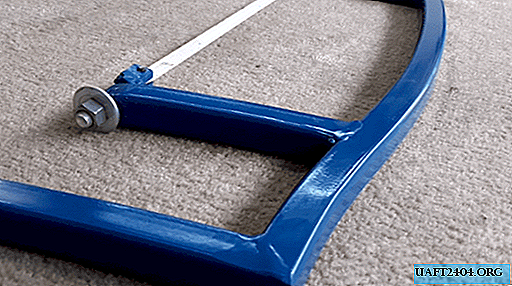

You can make a reliable and durable holder for a hacksaw blade for metal with your own hands from scraps of a profile pipe. A home-made metal frame-frame is a low-cost alternative to factory saws, which often turn out to be quite “fragile” and inconvenient to use.

The design of the holder for the hacksaw blade for metal is very simple, consists of cuts of profile pipes that need to be bent under a small radius, as well as the heads for tensioning the hacksaw blade. Due to the sufficiently strong tension, with the help of such a home-made saw, you can make accurate and accurate cuts.

The main stages of work

First, you need to bend the profile pipes under a small radius, and then cut the workpiece with the grinder of the desired size. In total, four pieces of the profile pipe (one long and three short) will be required.

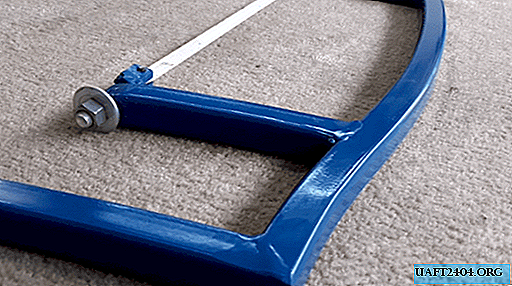

Then we cut two small pieces from the steel square, which will be used as the tension and clamping heads. They will need to make slots and holes to securely fix the hacksaw blade.

Holder frame assembly

We weld the horizontal tension head to the bolt with nut, and the vertical (clamping) head inside the extreme profile pipe. Then we make the final fitting and weld the holder frame. The result is a very comfortable frame.

We insert the tension web on the metal and with the help of a bolt with a tension head we adjust the desired tension force. For a detailed process of manufacturing and assembling a homemade holder for a hacksaw blade, see the video on the website.