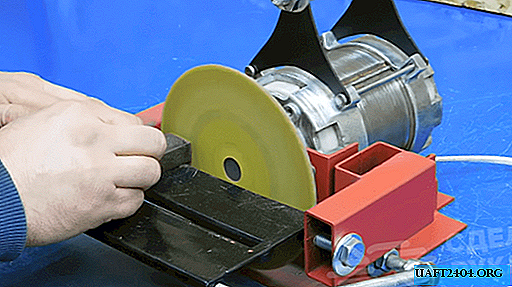

At a flea market, engines from Soviet-era washing machines or even modern products are often found. Such an engine is usually not expensive, but there can be a lot of benefit from it.

The idea is to make a grinding machine out of it, the performance of which can be even better than that of the Chinese counterpart. However, before buying it is advisable to check the performance.

To begin with, measure the resistance of the working and starting windings. The starting winding is of the greatest importance. We proceed to the production of the frame for our future machine. It must be stable and durable.

To form the frame, a metal corner and a profile pipe are used. Workpieces are cut. The engine is mounted on a part of the frame, and then the body is assembled around it completely by welding. Next, we make a table for the bed from the same profile pipe, cutting it in half.

The main stages of work

We weld a pair of pieces of round timber, forming a uniform gap between them and nuts at the edges. Under the table you need to focus. Then we make an additional part for fixing the required angle, which can be adjusted.

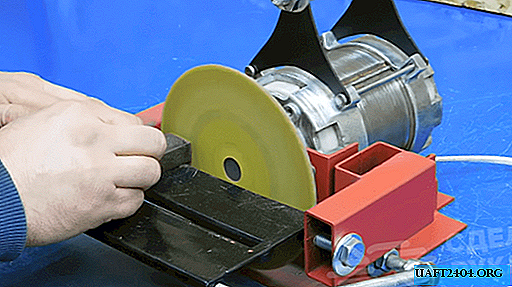

We take a disk from an old pneumatic grinder with a diameter of 150 mm. We cut the threads on the motor shaft and on the disk itself under the adapter from an elongated nut. If the engine is a capacitor, and its power is 180-200 W, we connect a starting capacitor at 12 microfarads (based on 7 microfarads per 100 watts).

We fasten one end to the motor wire, the other to one of the wires of the network cable. We place the capacitor near the engine with ties. Soundly isolate all the contacts and fix the network cable to avoid bias.

For the convenience of moving the machine, you can make a handle from a polypropylene pipe, inside which there is a metal rod. It is attached to the engine itself. We assemble the entire structure, install the disk and put our machine into operation.

The undoubted advantage of this design is that you can install interchangeable circles of absolutely any gradation. Also, with the pressure of the part on the surface of the abrasive, a significant reduction in speed does not occur, as on a Chinese grinding machine.

The machine is convenient and self-made quickly enough. See the video for a detailed assembly process.