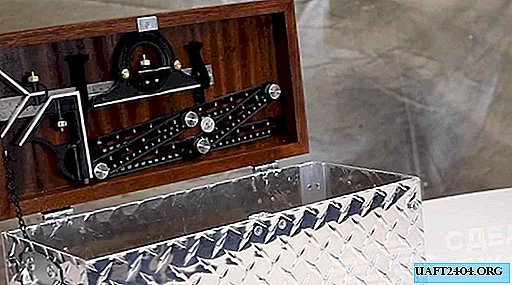

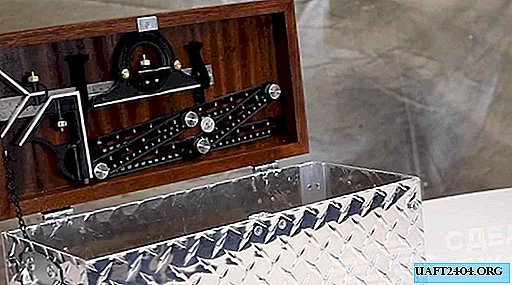

Coming to the object, the customer first of all meets the “clothing” master. In order to make a first impression, you need a good quality tool. But no less important is the packaging for the tool.

And in this review we will consider the manufacture of a beautiful and reliable suitcase for a manual or power tool. You can also present such a tool box as a gift.

For its manufacture, we need corrugated sheet metal, aluminum corners, wooden blocks, plywood and various accessories with hardware.

The main stages of work

First you need to cut out sheets of metal of suitable sizes and fix their joint to joint. In the corners of the joints we set the segments of the aluminum corner. We drill them in the right places and fasten them to the walls with bolts.

Next, we cut the bottom of our box from a piece of plywood. We also set the corners inwards and fix them with screws to the bottom, and to the walls using double-sided tape.

Let's make a cover from the bars sawed under 45 degrees, and boards. Choose a groove in the center of the board to the depth and the size of the corrugated sheet.

Hardware Installation

Next, proceed to the installation of accessories. We fix handles on the side walls for easy carrying. On the back wall we fasten the hinges, connecting them to the cover.

We fix a magnetic holder on the inner (front) wall, and on the lid there is a metal corner to hold it firmly when carrying it.

Inside, you can place various shelves for screwdrivers and fasteners for hand tools. In order to prevent the lid from falling back and outweighing the box, we will install a locking chain.

If you want to give an even more beautiful look to a suitcase, you can cover the lid with stain or mineral oil. The tool box is ready to use. A full description with all the nuances of the work can be seen in the video below.