From the anchor of a burnt electric motor, which can be found in any power tool (drill, grinder, screwdriver, etc.), you can make a universal grinding nozzle for a drill or screwdriver.

Using such a home-made grinding nozzle, you can perform various operations on the processing of workpieces made of wood or metal, so this tool in the workshop is definitely useful.

And to make the grinding nozzle is very simple. The engine can be removed from a burnt power tool or the anchor itself without a copper winding can be purchased for mere pennies at a metal receiver.

The main stages of work

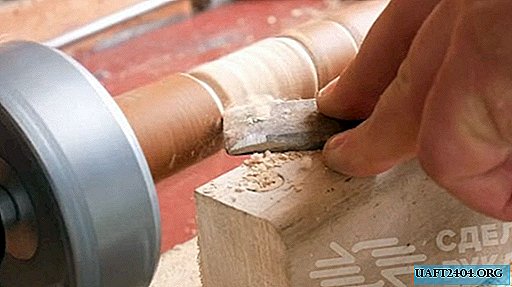

First of all, we remove the bearings from the engine and cut off everything unnecessary with a hacksaw. The shaft does not need to be cut off - it will serve as a shank that will be inserted into the drill or screwdriver chuck.

Next, using a gas burner, it will be necessary to burn out the varnish in the armature winding. Without this procedure, it will be impossible to get the copper wire. Or it will take a very long time.

Then the winding will need to be pry off with a screwdriver and pulled out using pliers. The anchor must be cleaned of slag and carbon deposits.

That's all there is to it - the very base of the nozzle is ready. Now it remains to cut the "petals" of the desired length from sandpaper and insert the anchors into the grooves. Or you can make such an option grinding, as shown in the photo below.

For details on how to make a grinding nozzle for a drill from an electric motor anchor, see the video on the website.