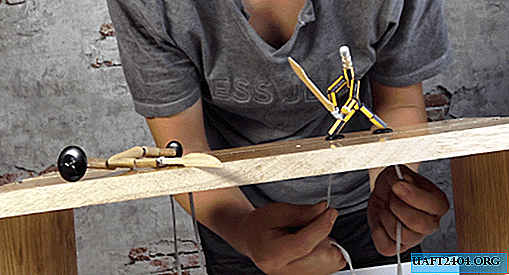

In this review, the author shares his own idea - how to make a simple fixture for the manufacture of plastic bags of different sizes from improvised materials.

To make such a device, the author uses pieces of laminate for this, connected together using two furniture hinges.

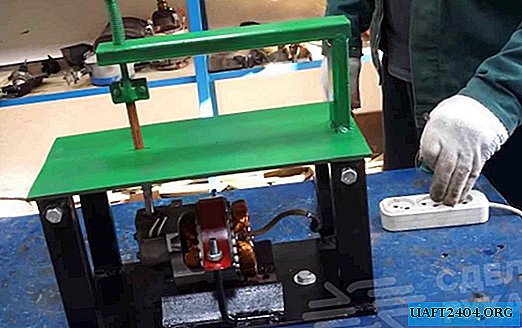

A stainless steel sheet (or ordinary sheet steel) 1 mm thick is also required.

On the surface of the base (laminate boards), the author made marking with a marker for the manufacture of plastic bags of certain sizes. This greatly speeds up the process.

Design features

As mentioned earlier, two pieces of laminate are interconnected using loops. Thanks to this, the homemade product is easy to fold.

To one of the laminate boards, the master attaches a stainless steel sheet 1 mm thick and a clamping bar, which is also made of stainless steel.

For cutting polyethylene into bags, a homemade roller is used, which is installed in an electric soldering iron.

Bag manufacturing technology

The technology itself is very simple and accessible to everyone. For the manufacture of packages, the author uses a roll of film 1.5 meters wide.

First, the film must be cut into strips of the desired width. The stripes are sealed on both sides.

After that, the cut strips must be cut into two parts. The result is ribbons that are soldered on only one side.

From these tapes, the author makes packages of the required sizes. A detailed process for making packages and an overview of the device itself can be seen in the video.