From a profile pipe 10x10 mm and a tree, the author will make a wall shelf in the hallway. It can store keys and other small things.

For the manufacture of shelves, the author decided to use forged elements that look very beautiful.

We recommend reading: a simple home-made jig for making curls in a garage or home workshop.

First of all, we cut off the workpieces of the desired length from the profile pipe. Then the author bends one blank with an arc and welds an even piece to it.

A wooden shelf will be attached to this frame. You can make a shelf out of plywood, but it will no longer look as noble as wooden.

The main stages of work

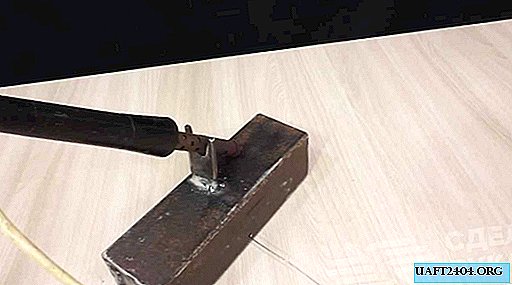

Further, on a makeshift machine for cold forging, the master makes two balusters (legs).

You will also need to make curls from a profile pipe: large and small (two pieces each).

At the next stage, cut a piece of a metal strip 40 mm wide, drill three holes in it and weld three balls.

After that we proceed to the welding work. First we weld large curls to the semicircle, the lower part of which will need to be welded to the strip.

Next, weld the legs and small curls. The author decided to weld steel balls to the ends of the profile pipe to look more original.

We clean the metal with a grinder and paint. Cut a wooden shelf, burn it and cover with varnish. Then we fasten to the frame.

For details on how to make a wall shelf in the hallway with your own hands from a pipe and tree, see the video on our website.