Share

Pin

Tweet

Send

Share

Send

Often there is such a problem - a boss has come off at the end of the cable, fixing it on the gas handle. Usually the problem is solved by replacing the cable assembly, but you can try to restore the latch, which I did with pleasure.

Necessary tools and materials

- Gas-burner;

- Angle grinder with a cutting disc;

- Drill (drilling machine) and a set of drills for metal;

- Pliers;

- File, knife;

- Calipers;

- Tin;

- Dielectric tape;

- A bolt 3-5 cm long and a piece of metal rod with a diameter of 6 mm (the length should be 2-3 cm longer);

Preparatory work

First of all, we measure the diameter of the hole (where the cable boss is inserted) on the gas handle using a caliper. It is 6 mm, so we need to take a drill bit for metal of the same size. We clamp the bolt in a vice, installing it vertically, and drill a through hole in the center.

Next, you need to make a side slot parallel to the length of the bolt up to 10 mm. We do this with a grinder, holding the bolt at an angle for convenience.

Next, install the pin in a vice and put on the prepared bolt with a slit up. The resulting recess should correspond to the thickness of the seat on the gas handle.

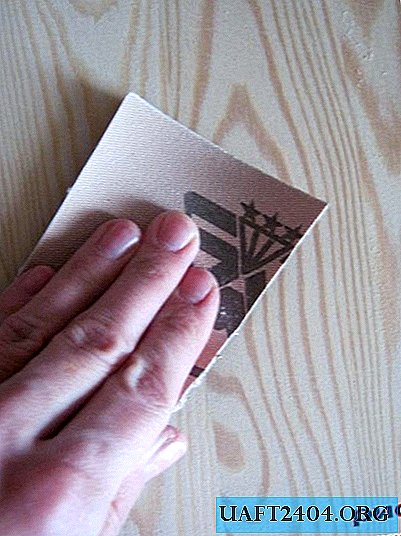

Next, we evenly cut off the torn end of the cable. To do this, it should be wrapped with electrical tape (enough in one layer) and make a neat cut with an angle grinder.

Smooth edge needs a little fluff. To do this, hold it in a pair of pliers and bend the cable fibers to the sides with any metal tool. The end of the cable thus prepared should be no more than 2-3 mm and placed in the hole of the bolt.

Boss casting

Through the slot we insert the fluffy edge of the cable into an impromptu casting mold.

Using a gas burner, we melt the tin so that it fills the void inside the bolt.

Next, we heat the upper part of the bolt and check the absence of voids with a piece of steel wire.

In the case of excess melt from above, just swipe them with a metal object until the tin has hardened, after which we allow the entire structure to cool.

Next, you should reinstall the pin in a vise, pulling it up 1 cm. Gently tapping the head of the bolt, push it deeper on the metal rod, which thus pushes our casting.

We remove the excess tin (where it was cut) with a knife and lightly process the edges of the boss with a file.

After that, you can install the cable on the gas handle by inserting the restored retainer into the seat. Pay attention to the lack of backlash of the boss - this will positively affect the service life of the restored connection.

Safety precautions

The implementation of the above actions requires compliance with a number of safety rules that are provided for working with power tools. Using the open flame of the burner, first make sure that there are no flammable and explosive objects nearby. Also, in no case do not neglect the personal protective equipment of the respiratory tract (respirator or mask) to protect yourself from the fumes of molten metal.

After the work done, you will have a casting form, and you can always help your friends if they have the same breakdown. In this case, recovery will take much less time.

Watch the process video

Share

Pin

Tweet

Send

Share

Send