Share

Pin

Tweet

Send

Share

Send

This is an incredibly simple way to solder aluminum you can imagine. With the help of it, anyone, at home or in the garage, can easily repair and restore any aluminum products, without any argon welding. You will easily make various designs from an aluminum profile and much more.

Now, to solder a radiator or aluminum bicycle frame, it is not necessary to go to the workshop and give a lot of money, everything can be soldered at home.

With a competent approach, soldering is no worse than a welded joint, but certainly more reliable than any cold welding, which is usually used as an alternative.

Will need

- Flux cored wire for brazing aluminum.

- Gas-burner.

A gas burner does not have to be professional. A normal gas nozzle burner nozzle is sufficient, or any other is suitable.

In more detail, I will talk about a specialized solder that will need to be purchased. This is a tubular powder solder specially designed for brazing aluminum (why powder? - powder inside the tube). It consists of two components: a shell and a powder base inside. We will not go into details about the chemical composition, this is useless.

It can be purchased in specialized stores, it is used in car repair shops. The most affordable way for everyone is to buy it on Ali Express - link to solder.

It is inexpensive, I advise you to take the packaging immediately - it’s definitely useful in life.

Soldering aluminum gas burner

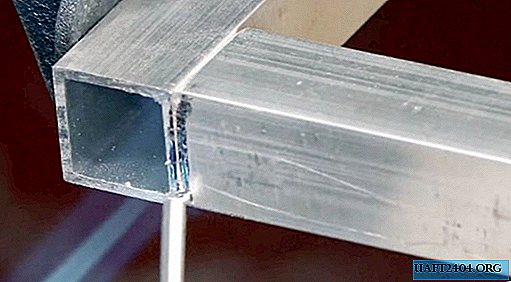

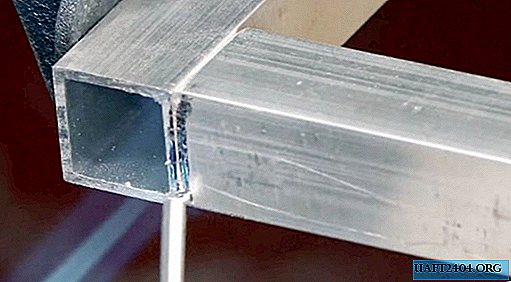

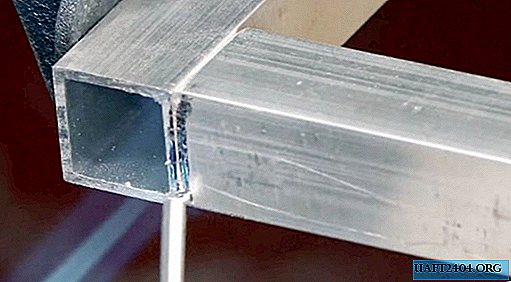

We take a profile or details that need to be welded.

We clean the surface with a brush for metal. As an option, you can take sandpaper with coarse grain. The larger the surface roughness for soldering, the better the bond with solder.

With a clamp or other device, fix the connection. Turn on the gas burner and heat the joint.

We bring the tubular solder. It melts and spreads along the seam.

The whole process takes place at about 450 degrees Celsius.

The solder has incredible fluidity and flows into any, even the smallest, cracks in the metal.

After distributing the solder, we warm the connection a little more so that it is distributed and spread out at the joints of the assembly as much as possible.

To summarize

Personally, when I found out about such a simple and affordable method of soldering, I was incredibly surprised. I think I managed to surprise you too, unless of course we knew about him before.

A few words about reliability. Of course, welding wins, since there is a union and mixing of structures, but this method is not much inferior. If the connection is bent, the part itself bends. The solder joint is extremely reliable and quite capable of withstanding almost any load, as if the joint was cast.

The only thing, if it turned out not quite high-quality soldering, is most likely not enough heating by the burner. In other cases, everything keeps tight.

Now to solder a hole in an aluminum pan, to make a bucket of sheet metal, to make a shelf from a profile for you is not difficult.

Take the armament method and use your friends! See you soon!

Share

Pin

Tweet

Send

Share

Send