Share

Pin

Tweet

Send

Share

Send

And if, for example, on the board of this LED flasher itself, two closed tracks accidentally go unnoticed? By connecting it to a powerful computer power supply unit, the assembled device can easily burn out if there is any installation error on the board. In order to prevent such unpleasant situations from happening, there are laboratory power supplies with current protection. Knowing in advance what kind of current the connected device will consume, we can prevent a short circuit, and, as a result, burnout of transistors and delicate microcircuits.

In this article, we will consider the process of creating just such a power supply, to which you can connect the load, without fear that something will burn.

Power supply circuit

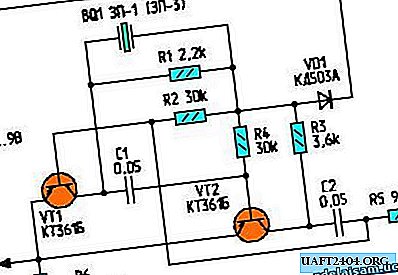

The circuit contains an LM324 chip, which combines 4 operational amplifiers, TL074 can be used instead. The operational amplifier OP1 is responsible for adjusting the output voltage, and OP2-OP4 monitors the current consumed by the load. The TL431 microcircuit generates a reference voltage of approximately 10.7 volts, it does not depend on the magnitude of the supply voltage. Variable resistor R4 sets the output voltage, resistor R5 can adjust the scope of the voltage change to your needs. Current protection works as follows: the load consumes the current that flows through the low-resistance resistor R20, which is called a shunt, the magnitude of the voltage drop across it depends on the current consumed. The OP4 operational amplifier is used as an amplifier, increasing the small drop voltage at the shunt to the level of 5-6 volts, the voltage at the OP4 output changes from zero to 5-6 volts depending on the load current. The OP3 cascade works as a comparator, comparing the voltage at its inputs. The voltage at one input is set by a variable resistor R13, which sets the protection threshold, and the voltage at the second input depends on the load current. Thus, as soon as the current exceeds a certain level, a voltage appears at the output of OP3, opening the transistor VT3, which, in turn, pulls the base of the transistor VT2 to the ground, closing it. A closed transistor VT2 closes the power VT1, opening the load power circuit. All these processes take place in a matter of fractions of a second.

Resistor R20 should be taken with a power of 5 watts to prevent its possible heating during long operation. The tuning resistor R19 sets the current sensitivity, the higher its rating, the greater the sensitivity can be achieved. Resistor R16 adjusts the protection hysteresis, I recommend not to get involved with increasing its rating. A resistance of 5-10 kOhm will provide a clear click of the circuit when the protection is triggered, a larger resistance will have the effect of current limitation, when the voltage at the output does not completely disappear.

As a power transistor, you can use domestic KT818, KT837, KT825 or imported TIP42. Particular attention should be paid to its cooling, because the whole difference between the input and output voltage will be dissipated in the form of heat on this transistor. That is why you should not use the power supply at a low output voltage and high current, the heating of the transistor will be maximum. So, let's move on from words to deeds.

PCB manufacturing and assembly

The printed circuit board is performed by the LUT method, which has been repeatedly described on the Internet.

An LED with a resistor, which are not indicated in the diagram, is added to the printed circuit board. The resistor for the LED is suitable for a nominal value of 1-2 kOhm. This LED turns on when the protection is activated. Also added two contacts, indicated by the word "Jamper", when they are closed, the power supply goes out of protection, "clicks off." In addition, a 100 pF capacitor was added between the 1 and 2 output of the microcircuit, it serves to protect against interference and ensures stable operation of the circuit.

Download board:

pechatnaya-plata.zip 20.41 Kb (downloads: 997)

Power Supply Setup

So, after assembling the circuit, you can begin to configure it. First of all, we supply power to 15-30 volts and measure the voltage at the cathode of the TL431 chip, it should be approximately equal to 10.7 volts. If the voltage supplied to the input of the power supply is small (15-20 volts), then the resistor R3 should be reduced to 1 kOhm. If the reference voltage is in order, we check the operation of the voltage regulator, when the variable resistor R4 rotates, it should change from zero to maximum. Next, we rotate the resistor R13 in its most extreme position, a protection may be triggered when this resistor pulls the input OP2 to the ground. You can install a resistor with a nominal value of 50-100 Ohms between the ground and the terminal end terminal R13, which is connected to the ground. We connect some load to the power supply, set R13 to the extreme position. We increase the voltage at the output, the current will increase and at some point the protection will work. We achieve the desired sensitivity with a trimming resistor R19, then you can solder a constant one instead. This completes the assembly process of the laboratory power supply, you can install it in the housing and use it.

Indication

It is very convenient to use the arrow head to indicate the output voltage. Digital voltmeters, although they can show voltage up to hundredths of a volt, constantly running numbers are poorly perceived by the human eye. That is why it is more rational to use arrow heads. It is very simple to make a voltmeter from such a head - just put a tuning resistor with a nominal value of 0.5 - 1 MΩ in series with it. Now you need to apply a voltage, the value of which is known in advance, and adjust the position of the arrow corresponding to the applied voltage with a trimming resistor. Successful assembly!

Share

Pin

Tweet

Send

Share

Send