Share

Pin

Tweet

Send

Share

Send

This is not the first time I am making something from PVC pipes. And I decided to share a new creation.

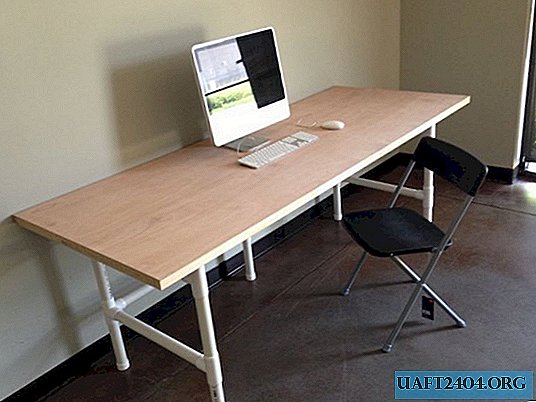

As the name of the master class shows, I will tell you how to make a large table out of a hollow door and plastic pipes. Such a table can be used as you like: as a workbench, desk, counter in the store and even as a table for a family meal. It all depends on your goal. We needed a dozen of these tables, and we use them as written ones.

Each table cost about 75 bucks.

The table fits perfectly into the atmosphere and looks quite decent. The countertop is perfectly smooth and can be repainted in any color. And his biggest advantage is his huge size, 90 cm wide and 200 cm long.

A few notes about this project:

Hollow countertop versus corpulent: I settled on the first option, as it is more economical, and we do not need tables that are too strong. If you are going to use the table as a workbench, then a solid door is better for a countertop. It will cost more and will be heavier (in fact, this is good). And the foundation will remain quite suitable for such an option.

About fittings: you will need a furniture set of fittings with plugs, fasteners for countertops and spatial crosses. You can reduce the cost of the table by replacing the connecting elements with ordinary plumbing, but then it will not look so good.

About pipes: for this project I stopped the choice of pipes that are used as hydrogen pipes. But if we do something similar in the future, then we will probably pick up furniture options that are more neat, strong and durable.

Table Tools

Instruments:

You will need a pipe cutting tool. It can be a hacksaw, special scissors or a miter saw. As you prefer.

An electric drill or screwdriver for connecting fasteners to the bottom of the countertop.

You will need at least fifteen short screws with drywall dowels. The dowels may not be needed, but sometimes you have to use them for more reliable fastening of the countertop.

Glue for plastic pipes, with which you can fix all the connections. The result should be a non-folding table. Alternatively, to fasten a fitting with a pipe, you can screw in 10 mm screws at the joints.

Base Details

As I said above, I used a furniture version of plastic fittings. Since I mainly needed a set of spatial crosses, fasteners and plugs. All other elements can be from the category of plumbing.

Here is a list of what I used:

- 5 plugs with a diameter of 1-1 / 4 inches.

- 5 fasteners with a diameter of 1-1 / 4 inches.

- 4 spatial crosses with a diameter of 1-1 / 4 inches.

- 4 tees with a diameter of 1-1 / 4 inches.

- 2 regular crosses with a diameter of 1-1 / 4 inches.

To reduce the cost of the project, I used plastic water pipes, but the furniture ones will be more accurate and durable, but at the same time expensive. I needed about 10 meters of pipe. It was cut into the following segments:

- 5 segments 8 cm long.

- 10 segments 30 cm long.

- 4 pieces 50 cm long.

- 4 pieces 50 cm long.

Assembly of the table: PARTY 1

In order to make it easier to understand what is attached to, I made a drawing.

Now let's get started.

Assembly: side 1.

The first thing to do is to assemble the sides of the table using various connecting elements, as shown in the figure. Fitting elements with a black outline and pipe lengths highlighted in red. This will look like the first or left side of the table.

I recommend that you first assemble it without gluing, then disassemble and apply glue to the fitting elements. As you probably guess, after gluing the parts it will be impossible to detach from each other.

Apply glue to the inside of the fitting where the pipe abuts against it. Make sure that the pipe enters the hole at the right angle, and only then use force to completely shrink it.

NOTES:

Most of the instructions say that glue is applied both to the inner surface of the fitting and to the end of the pipe, but I found this unnecessary.

If you do not want to use glue (since it is harmful when used indoors), you can use screws by screwing them in the place where the fitting is laid on the pipe.

I tried to make sure that the factory marking on the pipes was directed to the back of the table (where spatial crosses are). So they will not be evident, and subsequently they will not need to be removed with acetone. The photo shows that in one case I did not watch this moment. Learn from my mistakes.

Assembly: side 2.

The next stage of assembly is similar to the first, only now you need to make the second (right) side of the table, a mirror copy of the left side. Therefore, the spatial cross must look in the opposite direction.

Assembly: back

Now it's time to put together the back of the table, which is pretty simple. For this stage, you will need fasteners, plugs and two crosses. Connect the crosses on the sides to the 50 cm (30 ”) pipes as shown.

When you assemble and glue the central rack, this must be done in a horizontal position on the floor so that all the elements are in the same plane.

Table Assembly: Combining Parts

Now it is time to put everything connected with plastic into one design.

Connect the rear side pipes to the corresponding fitting elements on the right and left sides as shown. And again, I recommend that you first do everything without glue to make sure that everything fits together smoothly.

After you see that the elements can be glued, disassemble the parts and apply glue to the internal parts of the spatial crosses of the first side and insert the pipes of the rear part into them. Until the glue has dried, make sure that the parts are fastened evenly. Squeeze the parts for 30 seconds.

Next, apply glue to the corresponding elements of the second side and similarly connect it to the back. Press again for 30 seconds.

Now your base for the table is ready. And the table is almost ready.

Assembly: countertop

The problem with hollow doors: a hollow door consists of a frame and internal ribs, which are between the sheets for added strength. All voids are filled with cardboard, foam or remain empty.

Since it is difficult to determine where these ribs are located, we fix the worktops at random. If you find yourself in a void, use a dowel for drywall.

As the whole process takes place: lay the hollow door on the floor, with the side down, which should be the top of the countertop. Turn the PVC pipe structure over and place it on the door surface so that the fasteners are on the door.

Align the plastic frame so that it is centered and the fasteners should be equally spaced from the edges of the countertop. Then, using a pencil, make notes on where to screw the screws.

Remove the plastic structure from the countertop to the side. Using a drill or screwdriver, screw the screws into the marked spots.

If they come in easily, then you are in an empty place. Unscrew the screw and insert the dowel.

If the screw enters the door with effort, then you are in a wooden element of a frame or rib. Such fastening in itself will be reliable and no dowels are needed.

After you have determined in which places the dowels are needed and in which not, unscrew all the screws and place the plastic base on the countertop again to make sure that all the holes meet the holes of the fasteners.

NOTE:

All this can be avoided by using a solid door as a countertop. In my case, the hollow door was used only for the purpose of saving.

Finally, connect the countertop to the base with screws. You now have a fully assembled table that stands upside down.

Impregnation of countertops

Finally, you have a huge, sturdy, fully functional table.

Now you can apply paint or other products to the countertop. We decided to leave everything in its natural form, however, water spots strongly stand out on a thin surface, so we recommend using water-repellent impregnation or paint.

As with any other project involving plastic pipes, the size of the table can easily be changed depending on your needs. Doors are smaller, so the pipes can be made shorter. You can also increase the height of the table by replacing the pipe elements with a length of 8 cm with longer ones.

I hope you enjoyed reading this workshop.

Original article in English

Share

Pin

Tweet

Send

Share

Send