Share

Pin

Tweet

Send

Share

Send

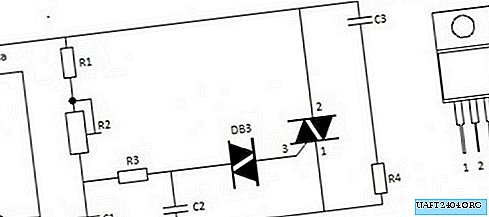

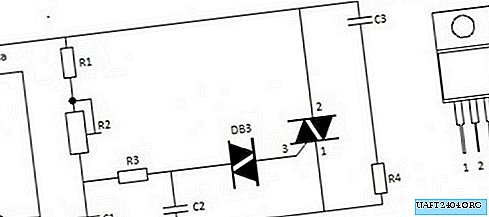

Scheme of a simple triac controller

Such a regulator can be used in regulating lighting with incandescent lamps, but also with LED, if you buy dimmable ones. Adjusting the temperature of the soldering iron is easy. You can steplessly control the heating, change the speed of rotation of the electric motors with a phase rotor and many more where there is a place for such a useful thing. If you have an old electric drill, which does not regulate speed, then using this regulator, you will improve such a useful thing.

The article, using photographs, descriptions and the attached video, describes in great detail the entire manufacturing process, from collecting parts to testing the finished product.

I must say right away that if you are not friends with neighbors, then you can not collect the C3 - R4 chain. (Joke) It serves to protect against radio interference.

All parts can be bought in China on Aliexpress. Prices are two to ten times less than in our stores.

To make this device you will need:

- R1 is a resistor of about 20 Kom, with a power of 0.25 watts;

- R2 - a potentiometer of approximately 500 Kom, it is possible from 300 Kom to 1 Mohm, but better than 470 Kom;

- R3 is a resistor of about 3 K, 0.25 W;

- R4- resistor 200-300 Ohms, 0.5 W;

- C1 and C2 - capacitors 0.05 MkF, 400 V;

- C3 - 0, 1 MkF, 400 V;

- DB3 - dinistor, is in every energy-saving lamp;

- BT139-600, regulates the current 18 A or BT138-800, regulates the current 12 A - triacs, but you can take any others, depending on what kind of load you need to adjust. The dinistor is also called a diac, the triac is a triac.

- The cooling radiator is selected from the value of the planned regulation power, but the more the better. Without a radiator, you can adjust no more than 300 watts.

- Terminal blocks can be put any;

- Use the breadboard as you wish, if only everything comes in.

- Well, without a device, as without hands. But solder is better to use ours. Although it is more expensive, it is much better. I did not see a good solder in Chinese.

Proceed to the assembly of the regulator

First you need to think about the arrangement of parts in such a way as to put as few jumpers as possible and solder less, then very carefully check the compliance with the circuit, and then we solder all the connections.

After making sure that there are no errors and placing the product in a plastic case, you can try it by connecting to the network.

Be very careful when testing. All parts of the circuit are under direct voltage of 220 volts and touching them is very dangerous.

If you completed the assembly correctly, then everything should work right away. The device does not need adjustment and adjustment.

Power regulator test

Share

Pin

Tweet

Send

Share

Send