Share

Pin

Tweet

Send

Share

Send

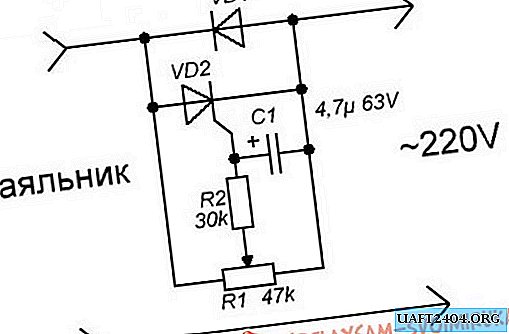

To build the device you will need:

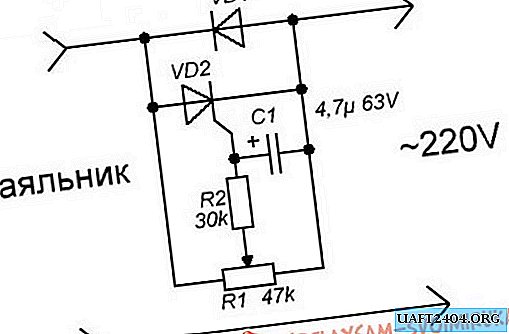

diode 1N4007 or any other, with a permissible current of 1A and a voltage of 400 - 600V.

thyristor KU101G.

- 4.7 microfarad electrolytic capacitor with an operating voltage of 50 - 100V.

- resistance 27 - 33 kilo-ohms with an allowable power of 0.25 - 0.5 watts.

Variable resistor 30 or 47 kilo-ohms SP-1, with a linear characteristic.

For simplicity and clarity, I drew the placement and interconnection of parts.

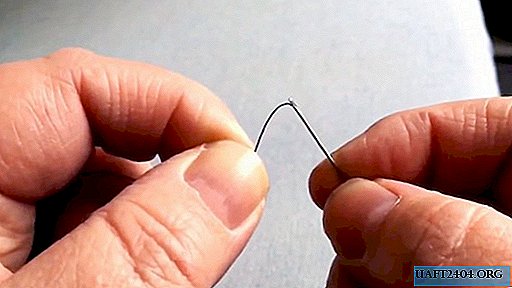

Before assembly, it is necessary to isolate and shape the findings of the parts. We put insulating tubes 20 mm long on the thyristor terminals, 5 mm on the terminals of the diode and resistor. For clarity, you can use colored PVC insulation, removed from suitable wires, or sit down shrink. Trying not to damage the insulation, we bend the conductors, guided by a drawing and photographs.

All parts are mounted on the terminals of the variable resistor, connecting to the circuit with four soldering points. We bring the conductors of the components into the holes on the terminals of the variable resistor, trim and solder everything. We shorten the conclusions of the radioelements. The positive terminal of the capacitor, the thyristor control electrode, the resistance terminal, are connected together and fixed by soldering. The thyristor case is an anode, for safety, we isolate it.

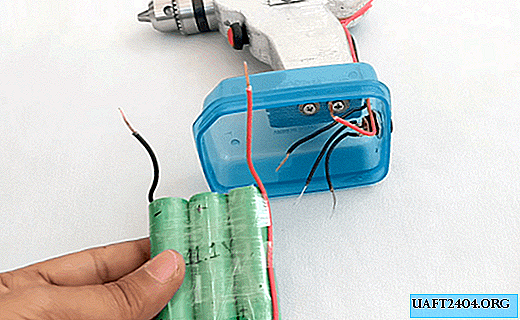

To give the design a finished look, it is convenient to use the housing from the power supply with a mains plug.

On the upper edge of the body we drill a hole with a diameter of 10 mm. We insert the threaded part of the variable resistor into the hole and fix it with a nut.

To connect the load, I used two connectors with holes for pins with a diameter of 4 mm. On the body we mark the centers of the holes, with a distance between them of 19 mm. In drilled holes with a diameter of 10 mm. insert the connectors, fix with nuts. We connect the plug on the case, the output connectors and the assembled circuit, the solder points can be protected by heat shrink. For a variable resistor, it is necessary to choose a handle made of insulating material of such shape and size to close the axis and nut. We assemble the case, securely fix the knob.

We check the regulator by connecting an incandescent lamp of 20 - 40 watts as a load. By turning the knob, we are convinced of a smooth change in the brightness of the lamp, from half brightness to full heat.

When working with soft solders (for example POS-61), an EPSN 25 soldering iron, 75% of the power is sufficient (the position of the regulator knob is approximately in the middle of the stroke). Important: on all elements of the circuit there is a supply voltage of 220 volts! Observe electrical safety precautions.

Author: Sergey Lavrentiev

[email protected]

[email protected]

Share

Pin

Tweet

Send

Share

Send